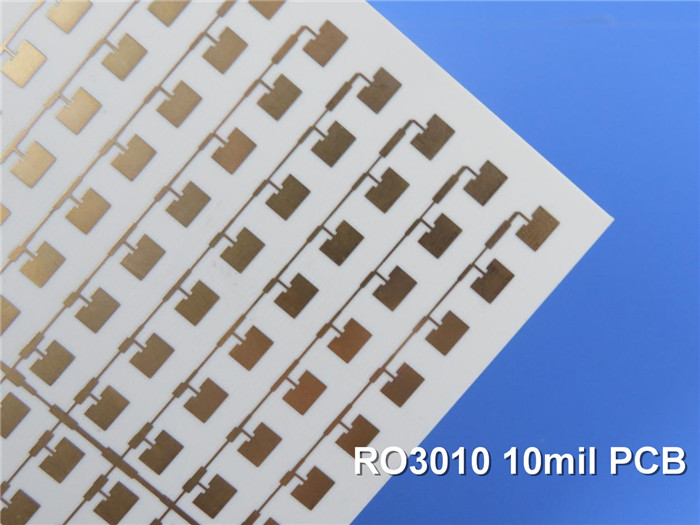

Rogers 3010 PCB RO3010 High Frequency PCB With 5mil, 10mil, 25mil and 50mil Coating Immersion Silver, Gold, Tin and HASL

(Printed Circuit Boards are custom-made products; the images and parameters shown are for reference only)

Overview:

Rogers RO3010 high frequency circuit materials are ceramic-filled PTFE composites, ideal for commercial microwave and RF applications. These materials offer exceptional electrical performance and mechanical stability at competitive prices. The consistent mechanical properties enable designers to create multi-layer board designs without issues such as warpage or reliability concerns.

Key Features:

1.Coefficient of Thermal Expansion (CTE): The X and Y-axis CTE is 17 ppm/℃, perfectly matched to that of copper. This ensures excellent dimensional stability with typical etch shrinkage of less than 0.5 mils per inch post-etch and bake.

2.Z-axis CTE: At 24 ppm/℃, this provides outstanding plated through-hole reliability, even in harsh environments.

Typical Applications

Automotive radar systems

Cellular telecommunications

Datalink on cable systems

Direct broadcast satellites

Global positioning satellite antennas

Patch antennas for wireless communications

Power amplifiers and antennas

Power backplanes

Remote meter readers

PCB Specifications:

Rogers RO3010 10mil 0.254mm High Frequency PCB for Direct Broadcast Satellites |

|

PCB SIZE |

91 x 85mm=1PCS |

BOARD TYPE |

Double sided PCB |

Number of Layers |

2 layers |

Surface Mount Components |

YES |

Through Hole Components |

YES |

LAYER STACKUP |

copper ------- 18um(0.5 oz)+plate TOP layer |

RO3010 0.254mm |

|

copper ------- 18um(0.5 oz) + plate BOT Layer |

|

TECHNOLOGY |

|

Minimum Trace and Space: |

4 mil / 8 mil |

Minimum / Maximum Holes: |

0.4mm / 0.8mm |

Number of Different Holes: |

n/a |

Number of Drill Holes: |

n/a |

Number of Milled Slots: |

0 |

Number of Internal Cutouts: |

0 |

Impedance Control: |

no |

Number of Gold finger: |

0 |

BOARD MATERIAL |

|

Glass Epoxy: |

RO3010 0.254mm |

Final foil external: |

1 oz |

Final foil internal: |

N/A |

Final height of PCB: |

0.3 mm ±0.1mm |

PLATING AND COATING |

|

Surface Finish |

Immersion Gold |

Solder Mask Apply To: |

Bottom, 12micron Minimum |

Solder Mask Color: |

Green, PSR-2000GT600D, Taiyo Supplied. |

Solder Mask Type: |

LPSM |

CONTOUR/CUTTING |

Routing |

MARKING |

|

Side of Component Legend |

Bottom |

Colour of Component Legend |

White, IJR-4000 MW300, Taiyo brand |

Manufacturer Name or Logo: |

Marked on the board in a conductor and leged FREE AREA |

VIA |

N/A |

FLAMIBILITY RATING |

UL 94-V0 Approval MIN. |

DIMENSION TOLERANCE |

|

Outline dimension: |

0.0059" |

Board plating: |

0.0029" |

Drill tolerance: |

0.002" |

TEST |

100% Electrical Test prior shipment |

TYPE OF ARTWORK TO BE SUPPLIED |

email file, Gerber RS-274-X, PCBDOC etc |

SERVICE AREA |

Worldwide, Globally. |

.jpg)

Data Sheet of Rogers 3010 (RO3010)

RO3010 Typical Value |

|||||

Property |

RO3010 |

Direction |

Units |

Condition |

Test Method |

Dielectric Constant,εProcess |

10.2±0.05 |

Z |

|

10 GHz/23℃ |

IPC-TM-650 2.5.5.5 Clamped Stripline |

Dielectric Constant,εDesign |

11.2 |

Z |

|

8GHz to 40 GHz |

Differential Phase Length Method |

Dissipation Factor,tanδ |

0.0022 |

Z |

|

10 GHz/23℃ |

IPC-TM-650 2.5.5.5 |

Thermal Coefficient of ε |

-395 |

Z |

ppm/℃ |

10 GHz -50℃to 150℃ |

IPC-TM-650 2.5.5.5 |

Dimensional Stability |

0.35 |

X |

mm/m |

COND A |

IPC-TM-650 2.2.4 |

Volume Resistivity |

105 |

|

MΩ.cm |

COND A |

IPC 2.5.17.1 |

Surface Resistivity |

105 |

|

MΩ |

COND A |

IPC 2.5.17.1 |

Tensile Modulus |

1902 |

X |

MPa |

23℃ |

ASTM D 638 |

Moisture Absorption |

0.05 |

|

% |

D48/50 |

IPC-TM-650 2.6.2.1 |

Specific Heat |

0.8 |

|

j/g/k |

|

Calculated |

Thermal Conductivity |

0.95 |

|

W/M/K |

50℃ |

ASTM D 5470 |

Coefficient of Thermal Expansion |

13 |

X |

ppm/℃ |

23℃/50% RH |

IPC-TM-650 2.4.4.1 |

Td |

500 |

|

℃ TGA |

|

ASTM D 3850 |

Density |

2.8 |

|

gm/cm3 |

23℃ |

ASTM D 792 |

Copper Peel Stength |

9.4 |

|

Ib/in. |

1oz,EDC After Solder Float |

IPC-TM 2.4.8 |

Flammability |

V-0 |

|

|

|

UL 94 |

Lead-free Process Compatible |

Yes |

|

|

|

|